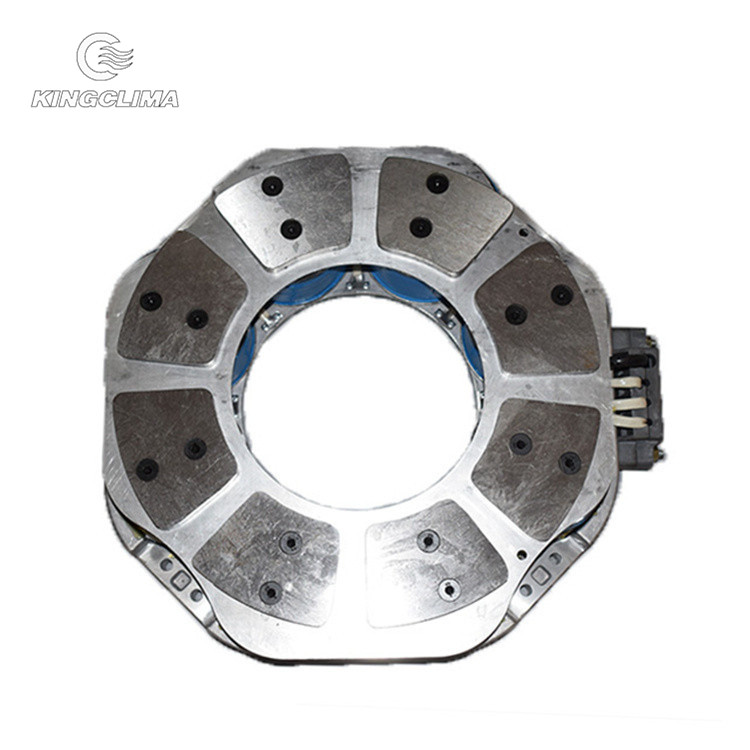

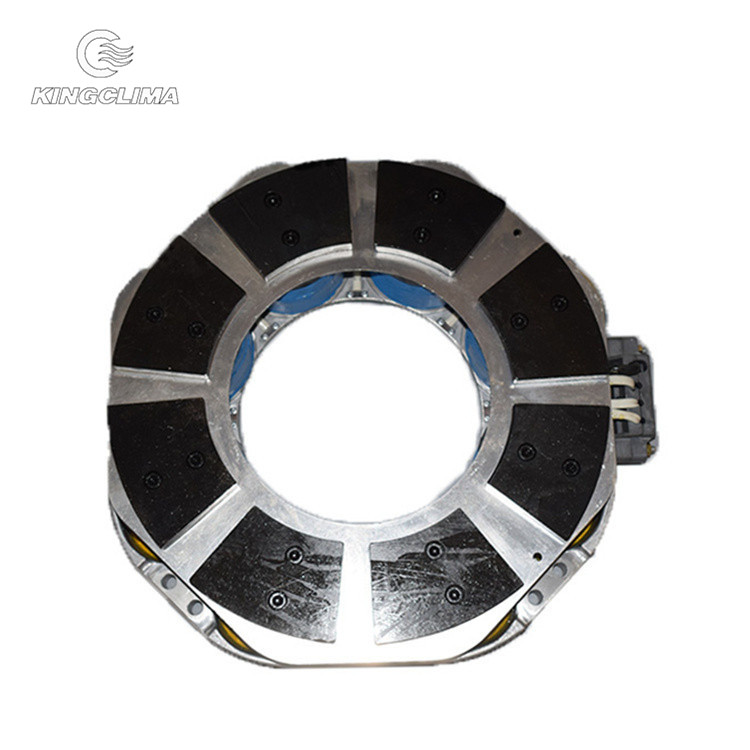

Eddy current retarder parts Rotor for TELMA bus brake

The rotor refers to the main rotating part of the retarder.

It is composed of symmetrical front and back turntables, which are fixed as a whole through flange or connecting ring in the middle. High speed rotation with the drive shaft. The use of special material — 12 Cr molybdenum-vanadium (trace element) + iron = high temperature resistance (retarder high temperature can produce more than 500 degrees of heat, the whole rotor red, easy to deformation, if add 12 Cr molybdenum-vanadium, will not be deformed).

The rotor is called armature core, and armature winding is installed on it. It generates induced electromotive force after being energized and acts as a rotating magnetic field to generate electromagnetic torque for energy conversion.

Contact US

Get Price

Share:

Content

Inquiry

More Eddy Current Retarder